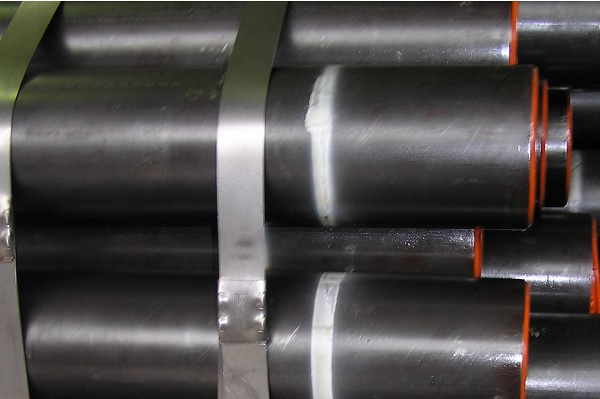

Steel grades for precision standard welded tubes

| EN 10305-2 | E235 (E155, E195, E275, E355 – by agreement) |

| Marking of steels according to EN standards: E – steels for machine parts 235 – minimum yield strength in N/mm2 +N – normalized +A – soft annealed +LC – cold drawn / soft +C – cold drawn / hard | |