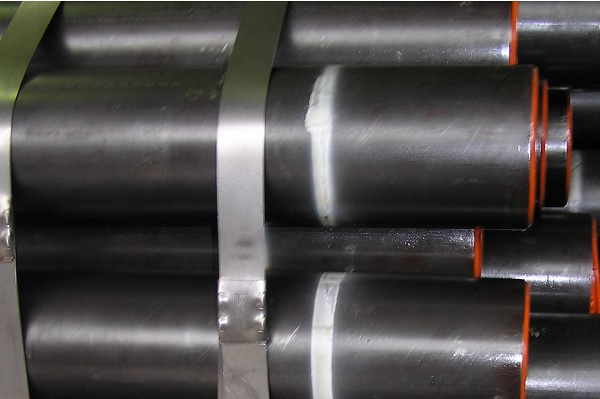

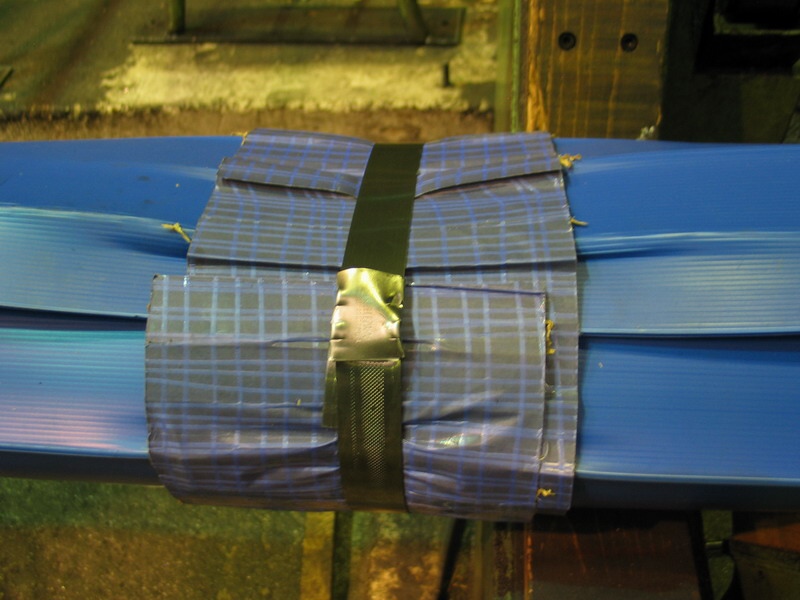

Length of bearing tubes

length 3 000 mm with tolerance +/- 500 mm.

Testing of bearing tubes

Testing is done according to DIN 17 230.

Tolerances of tubes for bearing production

| outside diameter D < 50 mm | 0 – +0.15 mm |

| outside diameter D > 50 mm | 0 – +0.25 mm |

| wall thickness | -/+ 7,5 % (after agreement 5 -/+ %) of the wall thickness |

Ends of the bearing tubes

Tubes have its ends smooth, plain square cut ends, one beveled 0,5 to 4,00 x 45°.