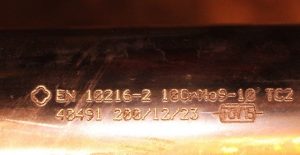

Steel grades for tubes intended for pressure equipment

| EN 10216-2 | P195GH, P235GH, P265GH, 16Mo3, 14MoV6-3, 7CrWVMoNb9-6, 7CrMoVTiB10-10, 10CrMo5-5, 13CrMo4-5, 10CrMo9-10, 25CrMo4, X11CrMo5+I, X11CrMo5+NT1, X11CrMo5+NT2, X10CrMoVNb9-1 |

| ASTM A 106 | Grade A, Grade B, Grade C |

| ASTM A 209 | Grade T1, Grade T1a, Grade T1b |

| ASTM A 210 | Grade A-1, Grade C |

| ASTM A 556 | Grade A2, Grade B2, Grade C2 |

| ASTM A 335 | Grade T/P11, Grade T/P12, Grade T/P22, Grade T/P24 |

| ASTM A 213 | Grade T/P11, Grade T/P12, Grade T/P22, Grade T/P24 |

| EN 10216-1 | P195TR1, P235TR1, P265TR1, P195TR2, P235TR2, P265TR2. |

| ASTM A 53 | Grade A, Grade B |

| EN 10216-3 | P355N, P460N, P355NH, P460NH, P275NL1, P355NL1, P460NL1, P275NL2, P355NL2, P460NL2. |

| EN 10216-4 | P215NL, P265NL. |

| ASTM A/SA 333 (A999) | Grade 1, 3, 6, 7 |

| ASTM A/SA 334 (A1016) | Grade 1, Grade 6 |

| ASTM A/SA 524 (A530) | Grade II |