Steel grades for hydraulic cylinders

| EN 10305-1 | E355 |

| EN 10 294-1 | 20MnV6 |

| STN/ČSN 42 0260 | 11 523 |

| DIN 2391-2 | St52 |

| DIN 17100 | St52-3 |

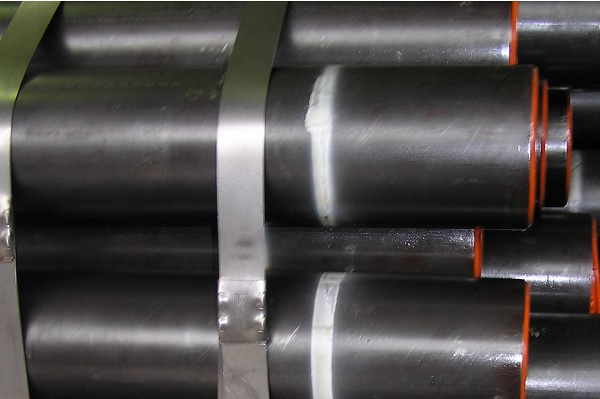

Tubes for mechanical machining – type HPZ are precision seamless tubes for the production of hydraulic cylinders or seals of piston rods. The inner working surface is obtained by mechanical machining, by honing or peeling and subsequent rolling.

Tubes intended for direct use in the cylinders – type HP are seamless tubes with a precisely machined inner surface, which are primarily intended for the manufacture of hydraulic cylinders. The inner working surface is achieved by peeling and subsequent rolling of the inner surface of the tubes.

Tubes intended for piston rods and telescopic cylinders – type HPK are cold drawn seamless tubes for piston rods, telescopic cylinders and cylinder liners. Use of tube piston rods and pistons is often preferable than the use of solid materials. Use of the tube material, which exhibits the same resistance to load stress, bending and in torsion, means a significant reduction in the weight of the cylinder.

| INNER DIAMETER (ID) | 40,0 – 115,0 mm |

| WALL THICKNESS (WT) | 5,0 – 10,0 mm |

| EUROPEAN STANDARDS | EN 10305-1, DIN 2391, STN/ČSN 42 6711, STN/ČSN 42 6712 |

| INNER DIAMETER (ID) | 40,0 – 110,0 mm |

| WALL THICKNESS (WT) | 4,0 – 10,0 mm |

| EUROPEAN STANDARDS | EN 10305-1, DIN 2391, STN/ČSN 42 6711, STN/ČSN 42 6712 |

| OUTER DIAMETER (OD) | 40,0 – 120,0 mm |

| WALL THICKNESS (WT) | 5,0 – 10,0 mm |

| EUROPEAN STANDARDS | EN 10305-1, EN 10294-1, DIN 2391 |

| EN 10305-1 | E355 |

| EN 10 294-1 | 20MnV6 |

| STN/ČSN 42 0260 | 11 523 |

| DIN 2391-2 | St52 |

| DIN 17100 | St52-3 |

Tolerances of the outside diameter (OD) HPZ tubes meet the appropriate dimensional table standards. Tolerances values of the inside diameter (ID) are presented in the table .

Tolerance of the wall thickness is -/+ 7.5% of the wall thickness.

HPZ tubes eccentricity is included in the wall thickness tolerance

Tolerances of the outside diameter (OD) HP tubes meet the appropriate dimensional table standards DIN 2391-1, EN 10305-1. Tolerances values of the inside diameter (d) H8 a H9 are presented in the table.

Tolerance of the wall thickness is -/+ 7.5% or 10% of the wall thickness.

HP tubes eccentricity is included in the wall thickness tolerance.

(a), manufactured length of precision tubes in the range of 3 to 6 meters

(b), maximum precise length 6 meters

Selection of the tests is either according to standards or upon agreement with customer:

• cast / chemical analysis,

• tensile test,

• dimensional inspecti,

• visual inspection,

• NDT to find longitudinal defects.

Other tests are possible upon agreement.

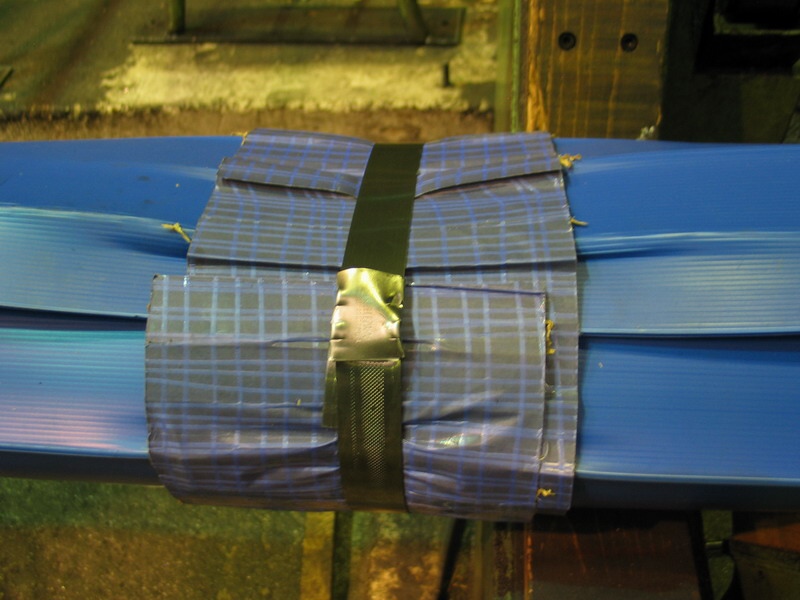

Upon agreement the tubes may be capped with plastic caps.

The surface of the tubes is oiled.

Tube are packed in round or hexagonal bundles with weight max. 2 000 kg, fastened with steel strips.

The tubes are marked along the length of the tube where the following pieces of information are used:

(a), manufacturers’ logo,

(b), dimension (OD x ID),

(c), steel,

(d), heat number,

(e), the number of standard,

(f), other data as per the customers’ request.

Straightness of the tubes is 0,001 multiple of the tube length maximum, allowed straightness for one meter length is 1.0 milimeters.

The tubes are delivered as cold drawn and annealed to relieve the stress BKS (+SR).

Other delivery conditions are possible upon agreement.

Are you interested in cooperation? Send us an inquiry, or order the goods directly from stock.

+421 48 6451111 | admin@zelpo.sk

| Cookie | Duration | Description |

|---|---|---|

| cky-consent | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Necessary" category . |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Analytics" category . |

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Necessary" category . |

| cookielawinfo-checkbox-others | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Performance". |

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| li_gc | 2 years | Used to store consent of guests regarding the use of cookies for non-essential purposes |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

| Cookie | Duration | Description |

|---|---|---|

| _uetsid | 1 day | Bing Ads sets this cookie to engage with a user that has previously visited the website. |

| _uetvid | 1 year 24 days | Bing Ads sets this cookie to engage with a user that has previously visited the website. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | To store a unique user ID. Collects data on the user’s navigation and behaviour on the website. This is used to compile statistical reports and heatmaps for the website owner. |

| _clsk | 1 day | These cookies are set by Microsoft. They are used to calculate visitors, sessions, sources, and pages visited in an anonymous form for the Sites’ analytics reports. |

| _dc_gtm_UA-12090850-25 | 1 minute | This cookie is associated with sites using Google Tag Manager to load other scripts and code into a page. Where it is used it may be regarded as Strictly Necessary as without it, other scripts may not function correctly. The end of the name is a unique number which is also an identifier for an associated Google Analytics account. |

| _dc_gtm_UA-12090850-5 | 1 minute | This cookie is associated with sites using Google Tag Manager to load other scripts and code into a page. Where it is used it may be regarded as Strictly Necessary as without it, other scripts may not function correctly. The end of the name is a unique number which is also an identifier for an associated Google Analytics account. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_4EJEG00XN6 | 2 years | This cookie is installed by Google Analytics. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _hjAbsoluteSessionInProgress | 30 minutes | Hotjar sets this cookie to detect the first pageview session of a user. This is a True/False flag set by the cookie. |

| _hjFirstSeen | 30 minutes | Hotjar sets this cookie to identify a new user’s first session. It stores a true/false value, indicating whether it was the first time Hotjar saw this user. |

| _hjIncludedInPageviewSample | 2 minutes | Hotjar sets this cookie to know whether a user is included in the data sampling defined by the site's pageview limit. |

| _hjIncludedInSessionSample | 2 minutes | Hotjar sets this cookie to know whether a user is included in the data sampling defined by the site's daily session limit. |

| _hjSession_104013 | 30 minutes | Collects statistics on the visitor's visits to the website, such as the number of visits, average time spent on the website and what pages have been read. |

| _hjSessionUser_104013 | 1 year | Used to store information about the time a sync with the lms_analytics cookie took place for users in the Designated Countries |

| _hjTLDTest | session | To determine the most generic cookie path that has to be used instead of the page hostname, Hotjar sets the _hjTLDTest cookie to store different URL substring alternatives until it fails. |

| AnalyticsSyncHistory | 1 month | Used to store information about the time a sync with the lms_analytics cookie took place for users in the Designated Countries |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| ckf | 1 year | It helps you see your targeted ad. |

| et_pub[2blSSM] | 3 months | It helps you see your targeted ad. |

| et_pub[2blSSN] | 3 months | It helps you see your targeted ad. |

| et_pub[2blSTr] | 3 months | It helps you see your targeted ad. |

| euvf | 14 days | It helps you see your targeted ad. |

| euvh | 1 month | It helps you see your targeted ad. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| SM | session | Registers a unique ID that identifies the user's device during return visits across websites that use the same ad network. The ID is used to allow targeted ads. |

| uuid2 | 3 months | The uuid2 cookie is set by AppNexus and records information that helps in differentiating between devices and browsers. This information is used to pick out ads delivered by the platform and assess the ad performance and its attribute payment. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |